Moondrop Venus Flagship Full-Size Planar Headphone

£592.24

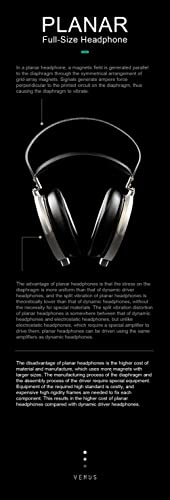

Planar Full-Size Headphone: The disadvantage of planan headphones is the higher cost of material and manufacture, which uses more magnets with larger sizes. The manufacturing process of the diaphragm and the assembly process of the driver require special equipment. Equipment of the required high standard is costly, and expensive high. rigidity frames are needed to fix each component. This results in the higher cost of planar headphones compared with dynamic driver headphones.

100mm Sub-Nanometer Diaphragm: Unlike other products, the stresses on the Venus printed circuit are distributed evenly during the vibration of the diaphragm, and other wiring has been recessed into the fixed part of diaphragm, ensuring that the whole diaphragm vibrates more evenly under ampere force. Compared with ordinary planar headphones, it further reduces the distortion caused by split vibration, and delivers a performance closer to that of electrostatic headphones.

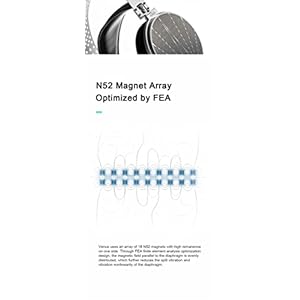

N52 Magnet Array Optimized by FEA: Venus uses an array of 18 N52 magnets with high remanence on one side. Through FEA finite element analysis optimization design, the magnetic field parallel to the diaphragm is evenly distributed, which further reduces the split vibration and vibration nonlinearity of the diaphragm.

Reviews

There are no reviews yet.